Machining an overview

-

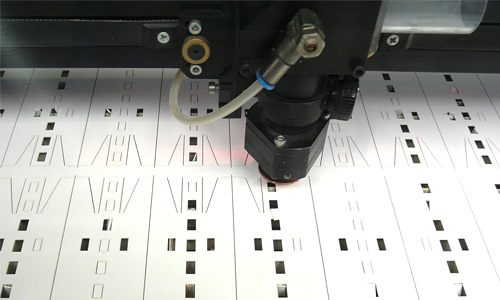

Laser cutting

Our ultramodern lasers are able to cut many different types of plastics, foils and sheet materials. Your DXF files can be easily converted into a file readable by our lasers. The edges immediately get, depending on the material, a matte or glossy finish.

-

Laser marking

In a fine raster a laser marks the texts, logos, maps and images. This high quality technology can be applied to any surface size from 1×1 mm to 3,050 x 2030 mm. Laser marking can be applied to a range of materials, especially our own production LuxxPlex Light Panels. A revolutionary product when combined with our, or your, energy efficient LEDs.

-

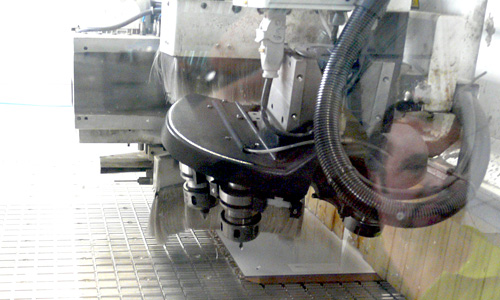

CNC-milling

In order to optimally mill sheet material ranging from 0.8 to 200 mm we use two advanced triaxial CNC-mills of 3,300 x 1,350 mm. Directly from DWG or DXF file to finished product.

-

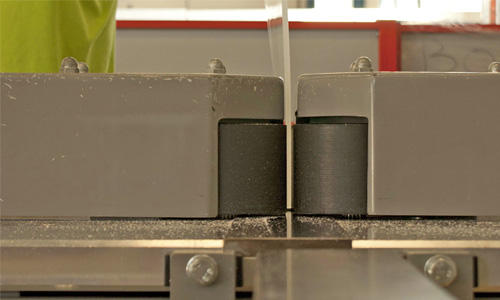

Sawing

Our production team has a CNC-controlled table saw measuring 4,500 x 2,500, which is able to saw optimally and precise (+/- 0.2 mm). We are able to saw from angles ranging from 0° to 45° with a maximum length of 3,050 mm.

-

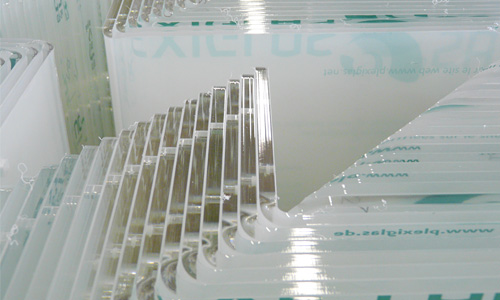

Diamond polishing

Diamond polishing gives the edges of the cut sheet metal a glossy finish. For precision finishing we use a sodium diamond cutter head.

-

Flame polishing

For flame polishing we use a flame of 1700 °C with which we give a glossy finish to the edges of the sheets. We use this technique when a simpler, more cost-efficient finish will suffice.

-

Brush polishing

Brush polishing is the traditional way to polish: sawing, scouring, waterproof scouring, brushing with polish. The result is beautiful and very suitable for high grade applications such as art.

-

Bending, setting and shaping

We bend nearly every plastic sheet. Our heaters have upper and lower coils, which provides for a more equal distribution of heat. This way we are able to bend materials with lengths ranging from 3 to 3,050 mm. Our molds department makes a perfect mold, for one-off use, or years of use. It’s also possible to set a mold without heat if the length is 2,400 mm or under.

We are able to heat plastics to a temperature of 250 °C which allows us to form sheets in one direction in a mold.

-

Gluing and Welding

We can apply using all high grade gluing techniques, both 1-component, 2-component, ultrasonic and ultraviolet. Plastics are accurately glued using both manual and automated dosing techniques according to predetermined procedures. Always in accordance to the latest technologies and within the latest regulations and laws.

Another field of our expertise is the welding of plastics. From wire welding to butt welding, our welds are sleek and strong.

-

Screen printing and Digital printing

Your printing is in safe hands with us, whether it is a conventional screen print or digital prints. We work with the best suppliers, for both cost-efficient projects and quality prints for high grade applications. Whether it is printing using UV-ink or 2-component paint for intensive applications, we always use the best machinery and the best paint for your custom work.

-

Tempering

Milling, lasering and scouring leave residual stresses in the materials. Our drying oven tempers these internal stresses. After tempering our products are virtually free of stress and therefore they are more durable in use.

-

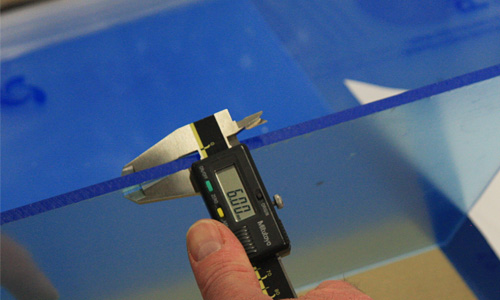

Quality control

Because quality is crucial for both you and us as a company, our products are checked multiple times during production. Your product is closely monitored on the quality of the material, width, dimensions and order amount. The last check is right before your product is shipped. That way you can be sure of a perfect product.

Address

Roosendaal • Netherlands

Company Info

VAT NL008251174B01

Contact

Europlex © 2024 | By 4 real solutions